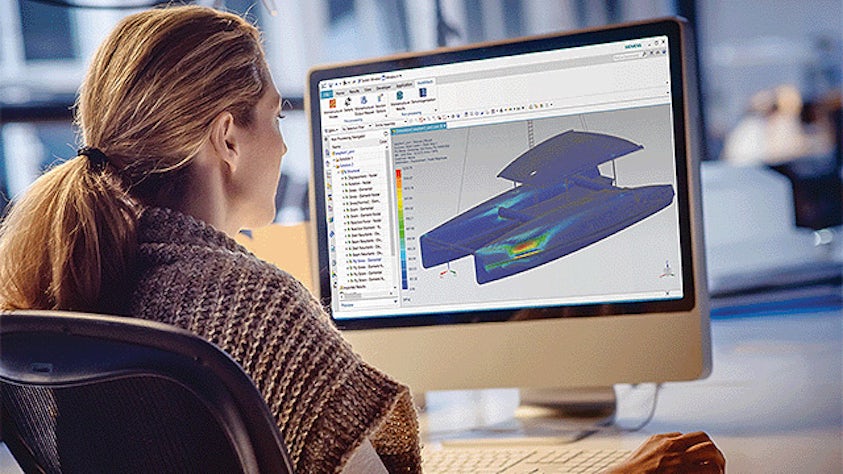

Why Simcenter 3D?

Simcenter 3D helps you model and evaluate complex product performance through revolutionary improvements in simulation efficiency. By integrating multiple physics domains together from a single simulation modeling environment, you gain better insight into your products’ performance faster.

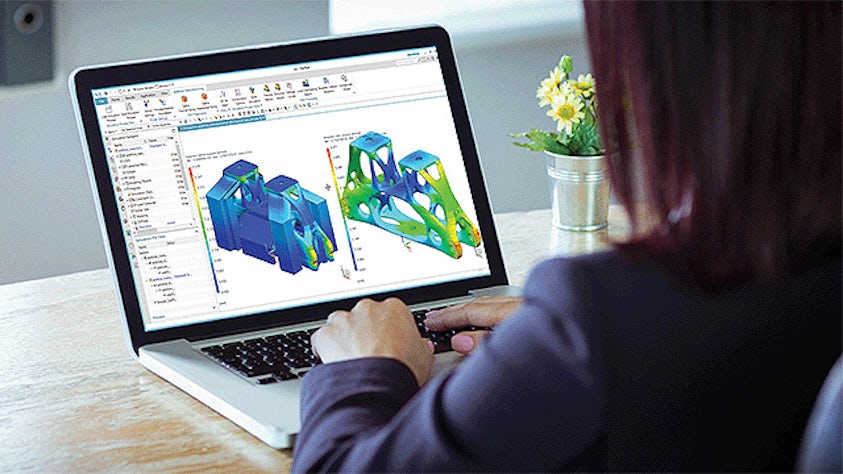

- Go faster – through a common engineering desktop

Simcenter 3D is an integrated CAE environment with powerful geometry manipulation tools for intuitive CAD geometry abstraction. Its meshing and modeling tools support multiple simulations, streamlining the modeling process and keeping analysis models synchronized with the latest design data.

- Model the complexity – by simulating many physics phenomena

Simcenter 3D integrates industry-standard simulation solvers for various physics domains within a centralized engineering environment. This streamlined integration facilitates multiphysics processes, making complex simulations more manageable and efficient.

- Explore the possibilities – through simulation automation

Simcenter 3D goes beyond reducing physical tests by automating design exploration through geometry and simulation parameter modifications. It also serves as a versatile pre- and post-processing tool for third-party solvers, offering excellent CAD associativity and meshing tools.

- Stay integrated – through seamless data management

Simcenter 3D, within the Simcenter simulation tools, seamlessly integrates with the digital thread, connecting 3D simulation, 1D simulation, and testing solutions. It maintains synchronization with digital development processes, including CAD, routing, product requirements, and manufacturing processes.

- Enjoy flexible licensing

To make Simcenter 3D even more flexible for your simulation team, Simcenter 3D offers value-based token licensing. Instead of purchasing individual licenses for each add-on module, you can buy packs of tokens that allow you and your team to instantly access most Simcenter 3D modules.

Simcenter 3D software capabilities

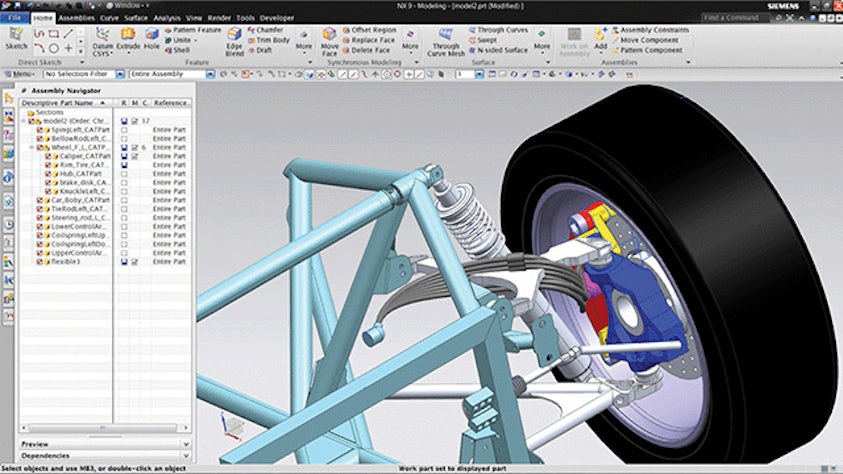

- Integrated, multidiscipline FE pre-/postprocessing

Simcenter 3D is a centralized environment for fast and streamlined pre-/post-processing across various solutions, facilitating multidiscipline simulations like thermal-mechanical or vibro-acoustic analyses. It enables quick geometry editing, comprehensive meshing, efficient finite element assembly management, and works seamlessly with third-party CAE solvers, allowing remote launch and monitoring.

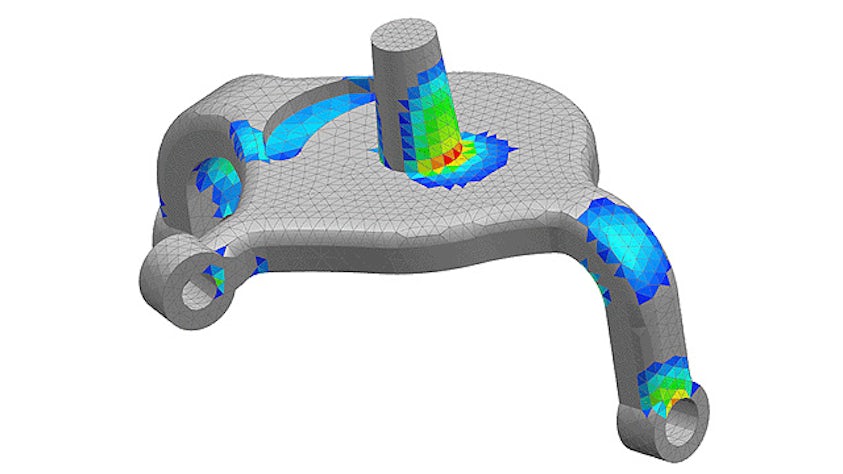

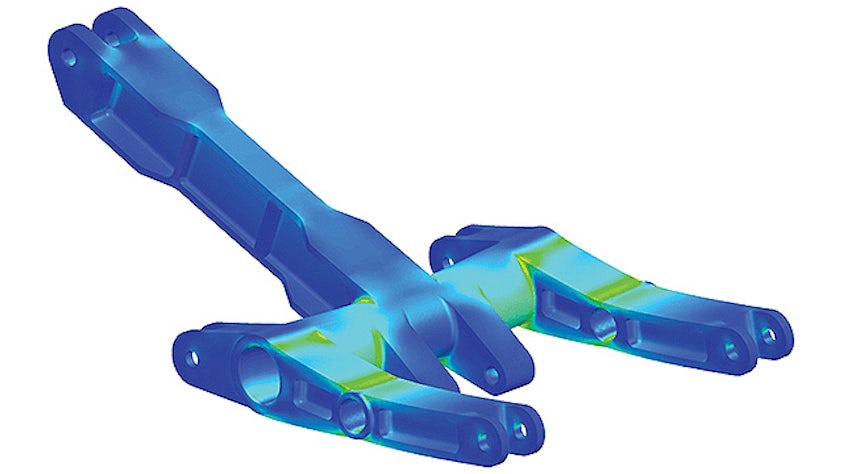

- Structural analysis

Simulate structures to understand how they perform for stress, deformation and more. Structural analysis solutions within Simcenter 3D are powered by the well-known Simcenter Nastran solver and can help you accurately simulate the following types of solutions:

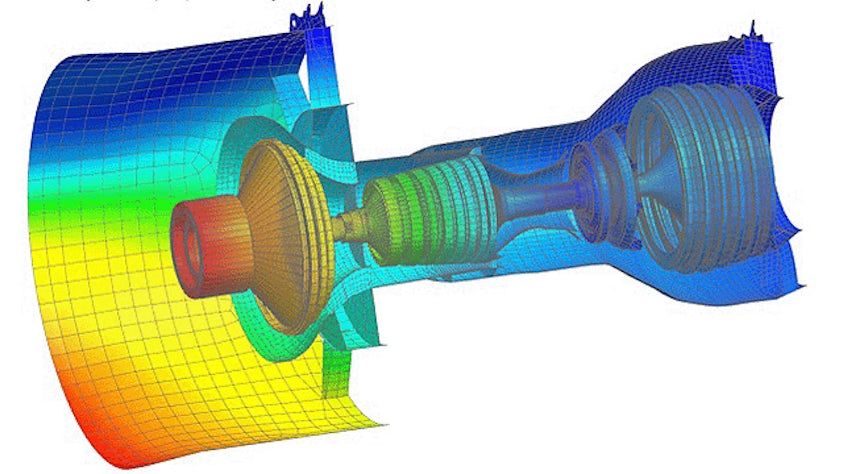

- Structural dynamics

Simcenter 3D offers efficient solutions for understanding and improving structural dynamics response. Dedicated capabilities include structural dynamics, noise, vibration, and harshness (NVH), rotor dynamics, and response dynamics.

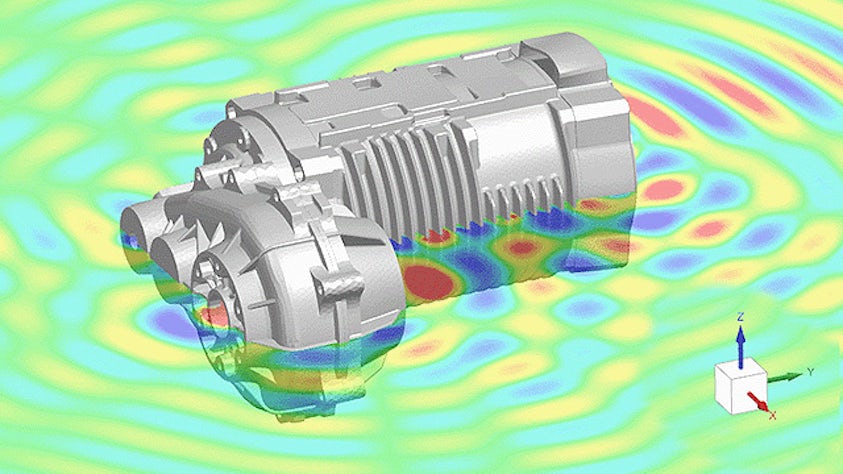

- Acoustic simulation

Simcenter 3D minimizes noise and optimizes sound quality with dedicated acoustic simulation capabilities. It offers efficient solvers and user-friendly visualization tools for insights into various acoustic applications, including Finite Element Modeling, aeroacoustics, and ray acoustics.

- Durability and fatigue analysis

Simcenter 3D supports thorough fatigue and lifing analysis across all development stages, with specific capabilities for fatigue strength, weld fatigue, and composite fatigue.

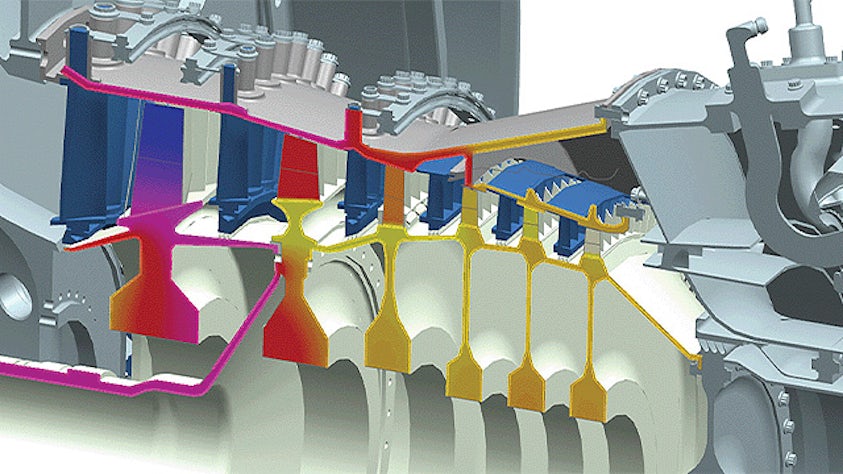

- Motion simulation

Simcenter 3D facilitates comprehensive multibody dynamics simulation, ensuring accurate evaluation of mechanism performance in various motions. Specific capabilities cover rigid and flexible body dynamics, control system integration, drivetrain, gears, interference checking, HIL, time waveform replication, driving dynamics, and tire model integration.

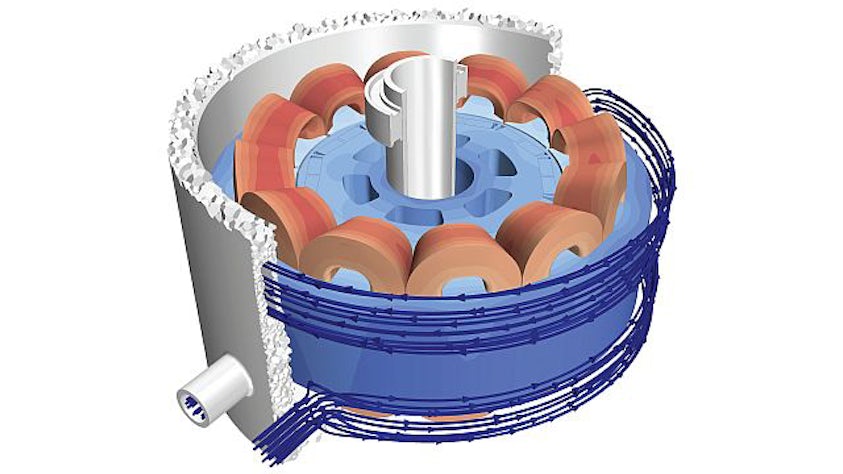

- Electromagnetics simulation

Integrate low-frequency and high-frequency electromagnetic solutions to achieve excellent performance. Simcenter 3D includes a comprehensive set of capabilities that provide insight into diverse design challenges, such as the performance of electromechanical components and energy conversion, antenna design and siting (small to large scale), electromagnetic compatibility (EMC) and electromagnetic interference (EMI).

- Materials engineering

Simcenter 3D speeds up product development with advanced materials, considering microstructural details and manufacturing variations. It enables the design of lighter, stronger, and more durable products through capabilities like multiscale material modeling and laminate composites modeling.

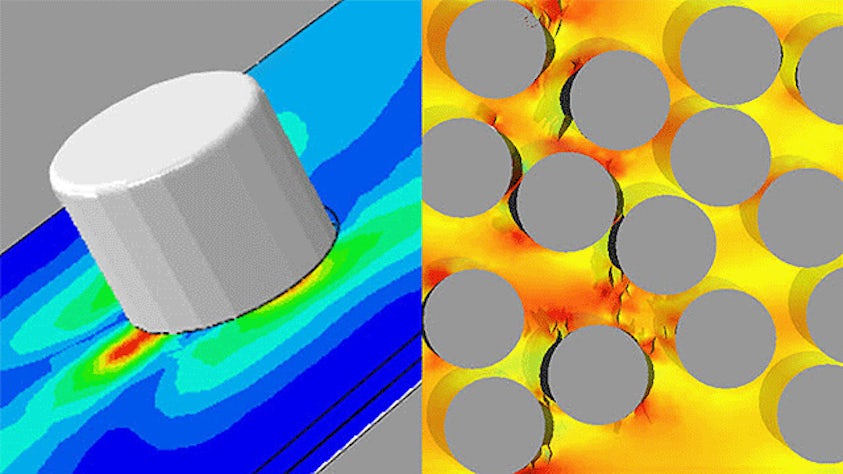

- Thermal analysis

Simcenter 3D provides a complete solution for modeling nonlinear and transient heat transfer. Its thermal analysis capabilities include conduction, convection, radiation heat transfer, conjugate heat transfer, and space-systems thermal analysis.

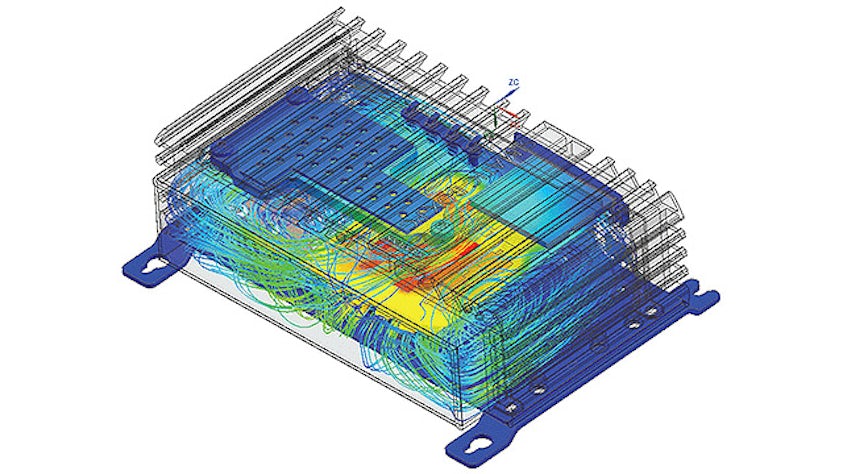

- Multiphysics

Simcenter 3D simplifies multiphysics simulations by integrating domain solutions in a common engineering desktop. It supports various simulations, including thermal-fluid, thermo-mechanical, fluid-structure interaction, vibroacoustics, aero-vibro-acoustics, electromagnetic-thermal, and electromagnetic-vibro-acoustic, with both weak and strong coupling options.

- Additive manufacturing build simulation

Simcenter 3D's additive manufacturing capabilities predict distortions and defects, minimizing the need for test prints and enhancing final print quality. Specific features include simulating the powder-bed fusion build process and geometry compensation based on results.

- Design space exploration and optimization

Simcenter 3D's optimization solutions automate the iterative process of improving product designs, allowing easy comparison against specifications. Capabilities include integrated design-space exploration, topology optimization, and FE parameter optimization.

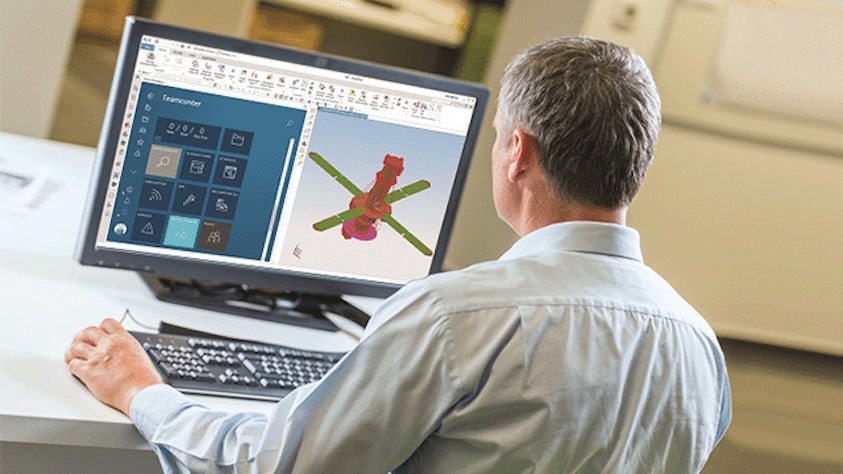

- Seamless data management

Simcenter 3D seamlessly integrates with Teamcenter, ensuring traceability of simulation work and data in product development. This combination allows efficient creation, storage, and retrieval of product simulation data in a controlled Teamcenter database.

- Flexible pipes, hoses and cables

Simcenter 3D simulates the movement of flexible pipes, hoses, and cables in moving assemblies. It analyzes mounting scenarios, calculates initial positions, and simulates behavior, supporting features like rubber-like hoses, electric cables, forces, moments, collision checking, and optimization of position and orientation in both linear and nonlinear dynamics.

- What’s New in Simcenter 3D 2206

- Automating simulation processes to streamline automotive design workflows

- Simcenter 3D solution guide