Why Simcenter Multimech?

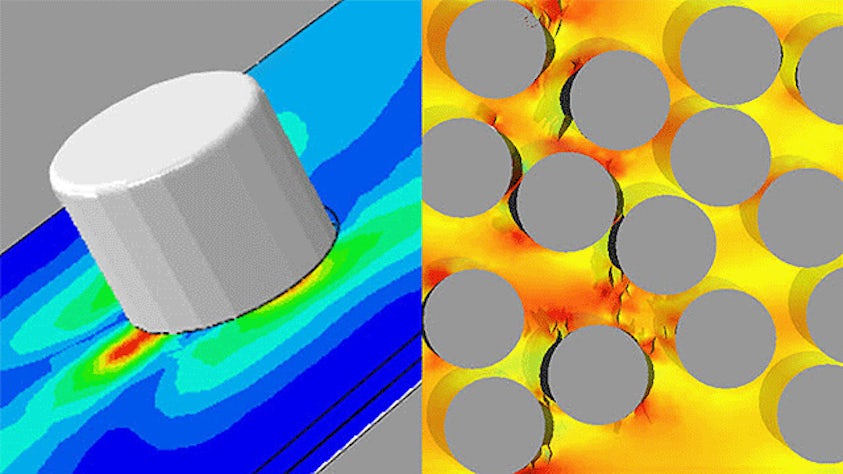

Predict how, when and why advanced materials may fail at the microstructural level. Simcenter Multimech is a multiscale material modeling and simulation software that extends the flexibility and robustness of the finite element method down to the microstructural level.

- Model material complexity with an adaptive multiscale approach

Advanced materials often behave in ways that are difficult to predict because of heterogeneity at the microstructural level. Simcenter Multimech strongly couples the part (macro) and material (micro) length scales and naturally embeds microstructural design variables into the design process. This gives your material models for simulation true degrees-of-freedom (DOF).

- Go faster without sacrificing accuracy

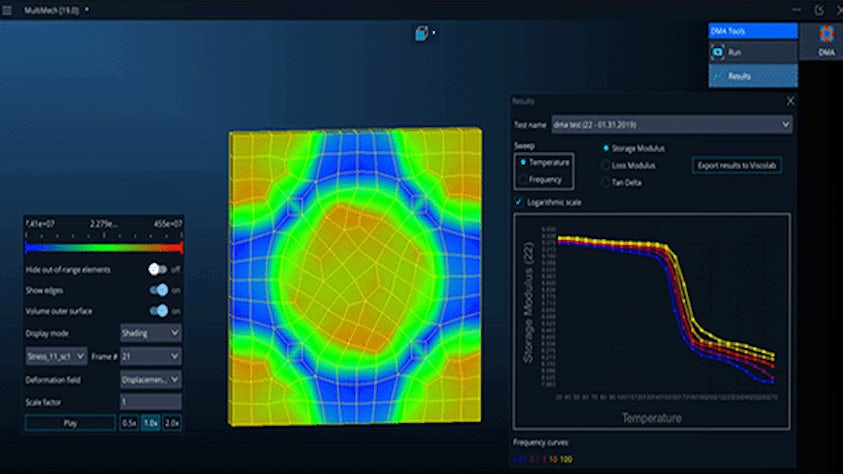

Physical testing of advanced materials is expensive and time-consuming. Simcenter Multimech multiscale solver technology provides unprecedented speed without sacrificing accuracy by combining two breakthrough innovations – a new mathematical formulation and an adaptive multiscale algorithm. Additionally, it is fully parallelized across threads and central processing unit (CPU) cores to achieve even greater gains in performance.

- Stay integrated with your preferred structural solutions

Don’t worry about having to sacrifice your preferred structural solver. Simcenter Multimech couples with the most popular structural solutions that engineers use today. Simcenter Multimech is an integrated solver within the Simcenter 3D platform, or you can also use Simcenter Multimech in combination with third-party finite element (FE) solvers Ansys and Abaqus.

- Virtual material and product design

Materials innovation is critical for improving performance and reducing the cost of products. However, the amount of physical testing required to develop and certify new materials challenges the speed at which you can introduce new materials innovation. Read this white paper to learn how adaptive multiscale modeling technology can help you with the virtual design of materials and complex products.

Read white paper

Simcenter Multimech capabilities

- Multiscale material modeling

Simcenter Multimech enables you to zoom into the material microstructure to identify the root cause of failure and see what damage mechanisms affect structural performance. Optimize your material microstructure for the most cost-efficient performance.

Materials engineering

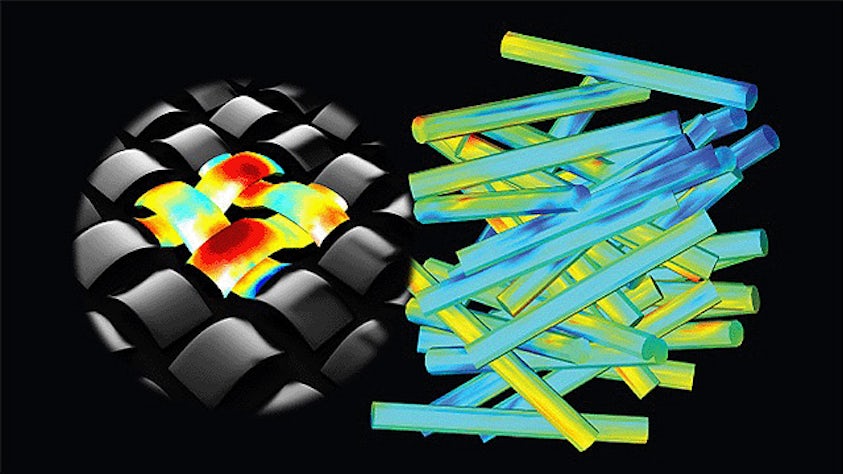

- Automatic microstructure generation and optimization

Automatically generate the geometry and meshing of your microstructural models. The only inputs required are basic design variables. You can also quickly and easily apply various loading scenarios to gain insight into how the material will perform in different conditions.

- Manufacturing variability and imperfections

Simcenter Multimech accounts for manufacturing variability and imperfections to maximize product reliability. Import process-induced variation data and automatically convert it to microscale, including volume fraction and fiber orientation tensors to simulate injection-molded parts.

- Virtual material development and modeling environment